Choosing the Right Tools and Best Practices for Workshop Management

Running a high-performing automotive workshop takes more than just a toolbox and a garage—it demands strategy, precision, and the right support system. Whether you’re servicing heavy-duty commercial vehicles or everyday passenger cars, workshop efficiency is what separates the best from the rest. Beekay Group, with its decades-long legacy in the automotive service industry, knows exactly what it takes.

Why the Right Tools Matter

At the core of every successful workshop are tools that are durable, precise, and tailored to the vehicle types being serviced. Beekay Motors, Beekay Group’s authorized Eicher Trucks & Buses workshop, services over 200 vehicles a month with 97% TAT (Turn Around Time) using dedicated repair bays and cutting-edge diagnostics equipment. This level of efficiency is only possible with the best tools.

Essential Workshop Tools Include:

-

Digital Diagnostic Scanners: For quick and accurate fault detection.

-

Hydraulic Lifts & Jacks: Safe and efficient vehicle access.

-

Torque Wrenches & Pneumatic Tools: Precision tightening for safety and performance.

-

Coolant & Fluid Flush Machines: Essential for modern vehicle maintenance.

Best Practices That Boost Productivity

Beekay Group’s proven workshop practices can serve as a guide for independent mechanics and service centers aiming to scale up their operations.

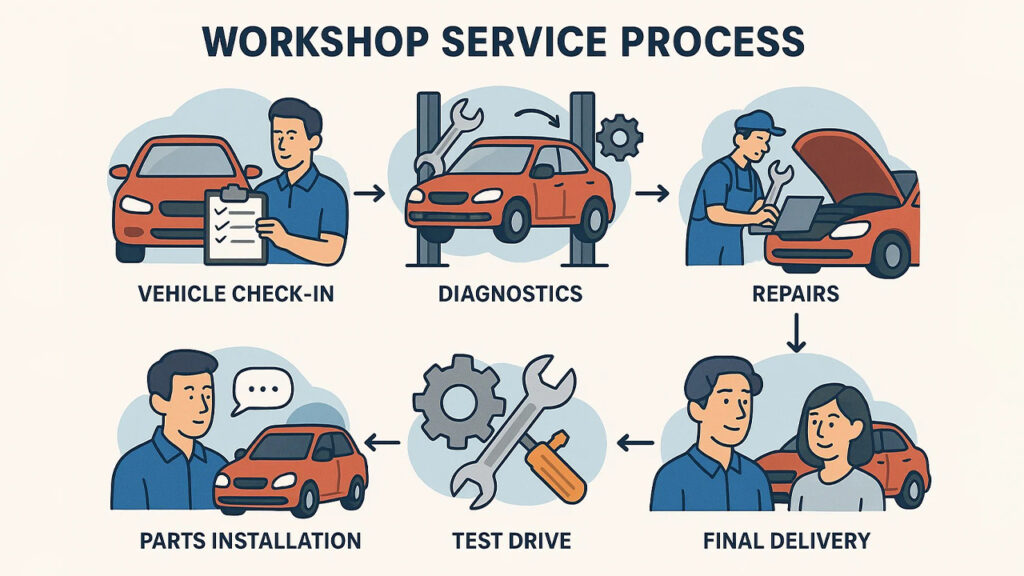

1. Process-Driven Workflow

Every service—from preventive maintenance to accidental repairs—should follow a clear workflow. Document check-ins, inspections, repairs, and test drives using job cards and digital logs.

2. Inventory Management

Ensure consistent availability of fast-moving parts. Beekay’s wide SKU catalog (8,000+ for Eicher alone) ensures that authorized workshops never face downtime due to unavailable parts.

3. Team Training and Upskilling

Your team is your biggest asset. Regular training on new models, updated equipment, and safety protocols boosts morale and improves service quality. Beekay’s team of experienced technicians are specialists in commercial vehicles—a core reason behind their customer trust.

4. Customer Communication

Maintain transparency through real-time updates, estimates, and follow-ups. Happy customers are returning customers, and Beekay’s “customer-first” mission is proof of how vital this is.

Beekay-Recommended Products for Workshop Excellence

To run a workshop aligned with OEM standards, using genuine parts, lubricants, and fluids is non-negotiable. Beekay Group proudly distributes:

-

Eicher, Mahindra, Maruti Suzuki, Tata, and Royal Enfield Genuine Parts

-

Shell Lubricants & DEF

-

Goodyear and BKT Tyres

These brands guarantee reliability, better performance, and longer vehicle lifespan—exactly what your customers want.

Final Thoughts

Efficient workshop management is about more than fixing vehicles—it’s about delivering consistent quality, building trust, and staying ahead with the right tools and practices. Beekay Group’s blend of decades-long experience and customer-centric approach is a model worth emulating.